Cost-Effective Strategies for Threat Detection in Manufacturing

Explore cost-effective threat detection strategies in manufacturing to reduce risks without inflating security budgets.

October 1, 2025

Manufacturing organizations face increasingly sophisticated cyberattacks that traditional security tools cannot detect fast enough. When ransomware paralyzed Varta AG's battery production across five plants, the manufacturer lost weeks of output while rebuilding critical systems from scratch.

The attack forced immediate shutdowns, corrupted industrial control systems, and demonstrated how cybercriminals now target the convergence of information technology and operational technology in manufacturing to inflict maximum damage.

Threat Landscapes Grow More Complex Every Day

Manufacturing faces an escalating threat landscape, with average breach costs reaching $5.56 million in 2024, according to IBM's latest report. Beyond financial losses, operational disruptions incur costs of thousands of dollars per minute in lost production, damaged equipment, and broken supply chain commitments.

Additionally, industrial control systems store valuable intellectual property, production formulas, and supplier data that attackers exploit through ransomware, espionage, and sabotage campaigns specifically designed for manufacturing environments.

These breaches create cascading failures that spread far beyond traditional IT incidents. Current ransomware attacks demonstrate unprecedented sophistication, with threat actors developing specialized capabilities for manufacturing environments. Manufacturing organizations face critical gaps in Operational Technology (OT) network monitoring, leaving industrial systems vulnerable to attacks that can cause production shutdowns, resulting in millions of dollars in daily costs.

Manufacturing organizations need AI-based threat intelligence systems specifically designed for manufacturing environments that understand the unique behavioral patterns of industrial systems, the complexities of OT/IT convergence, and the specific attack vectors that threat actors use against manufacturing targets.

That said, this article examines five proven strategies that strengthen threat detection within the manufacturing sector.

1. Understand Your Manufacturing-Specific Threat Landscape

Manufacturing organizations face distinct threats targeting industrial environments through specialized attack vectors. Three critical categories often go undetected by traditional threat intelligence:

Supply Chain Attacks: These exploit interconnected vendor ecosystems to gain legitimate credentials and potentially spread compromise across multiple organizations

Operational Technology (OT) Ransomware: Causes production shutdowns, equipment damage, and safety system failures with significant financial impact

Industrial Espionage: Targets proprietary processes, product designs, and supply chain relationships through long-term infiltration campaigns

According to the Cybersecurity and Infrastructure Security Agency (CISA), threat actors now "target specific OT products instead of specific organizations," suggesting fundamental shifts in attack methodology.

Organizations that develop a comprehensive understanding of their threat landscape often improve detection capabilities by focusing on manufacturing-relevant patterns rather than generic signatures. This specialized approach helps protect critical production infrastructure while addressing the convergence of IT and OT systems.

2. Map Your Manufacturing-Specific Attack Surface

A comprehensive attack surface assessment helps establish robust industrial cybersecurity foundations. Manufacturing environments encompass unique components and protocols that are absent from traditional IT networks.

The key assessment domains include network architecture at OT/IT convergence points often lacking segmentation; endpoint analysis covering programmable logic controllers (PLCs), distributed control systems (DCS), and safety systems running legacy software; industrial protocols that may lack security features; human factors considering engineering personnel targeted for social engineering; and physical infrastructure encompassing access controls and contractor management.

Attack surface mapping enables prioritized protection of production-critical assets. Organizations identifying these vulnerabilities achieve better resource allocation, faster incident response, and improved regulatory compliance. This systematic approach enables security teams to focus on areas with the greatest operational impact.

3. Choose Industrial-Grade AI Threat Intelligence Platforms

Manufacturing organizations benefit from AI platforms that integrate both IT and OT environments, while supporting industrial cybersecurity standards. The essential capabilities include:

Behavioral analysis trained on industrial patterns with supervisory control and data acquisition (SCADA) integration

Automated threat hunting that distinguishes operational variations from genuine threats

Native protocol support for Modbus, DNP3, and EtherNet/IP without disrupting operations

Compliance alignment with International Society of Automation (ISA)/IEC 62443 and NIST SP 800-82r3 guidelines.

Organizations using properly integrated platforms often experience improved threat detection and reduced analyst workload compared to signature-based systems. Platform selection has a direct impact on operational continuity and regulatory compliance.

4. Build Manufacturing-Aware AI Detection Models

Manufacturing environments require specialized AI models to recognize industrial patterns and minimize false positives while effectively detecting threats. Generic models may overlook manufacturing-specific indicators, resulting in security gaps.

Effective training involves recognizing unusual access patterns to engineering workstations during non-maintenance periods, abnormal data transfers involving computer-aided design (CAD) files outside operational schedules, communication anomalies between OT/IT networks that suggest lateral movement, and process deviations indicating control system manipulation.

Manufacturing AI detection employs deep learning for time-series industrial data analysis, ensemble methodologies combining rule-based systems with machine learning, and unsupervised algorithms detecting zero-day attacks. Additionally, the properly trained systems achieve improved accuracy while reducing false positives compared to generic platforms. This specialized approach helps maintain production continuity while strengthening security posture.

5. Implement Production-Aware Automated Response

Manufacturing automated response systems should consider production contexts and safety requirements before taking protective actions. Alert overload from systems unable to distinguish operational variations from threats can cause delayed responses and analyst fatigue.

Modern threat actors target specific OT products rather than entire organizations, making product-aware defense a crucial strategy. An effective response requires OT integration with programmable logic controllers (PLCs), distributed control systems (DCS), and safety instrumented systems (SIS); connectivity to a manufacturing execution system (MES) to understand current production states; and context awareness for determining appropriate response actions based on operational conditions.

Organizations with properly configured automated responses often achieve improved response times for critical OT events compared to manual processes. Context-aware automation helps prevent unnecessary production disruptions while maintaining security posture, balancing operational continuity with threat mitigation.

Where Abnormal Fits In

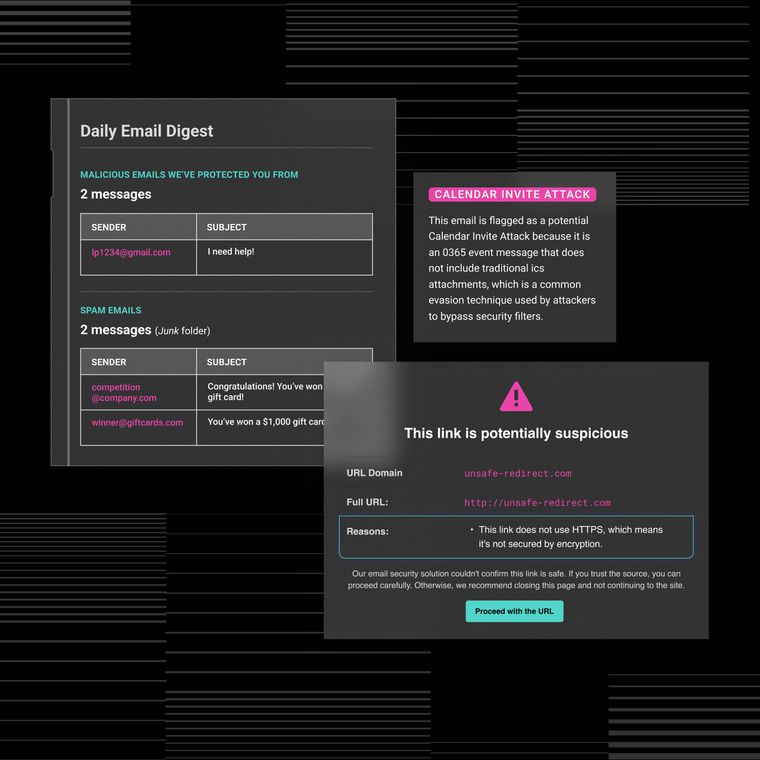

Abnormal addresses the unique challenges manufacturing organizations face by employing behavioral AI that baselines normal organizational behavior to detect deviations that traditional threat intelligence systems miss. Abnormal recognizes anomalies even in ongoing conversations, enabling immediate detection and remediation of threats that legacy systems overlook.

The behavioral AI approach specifically benefits manufacturing environments through continuous analysis of communication patterns and organizational behavior. This methodology proves particularly effective in detecting sophisticated supply chain attacks, insider threats, and social engineering attempts that target the complex vendor relationships and high-value intellectual property of manufacturing organizations.

Quantified results demonstrate significant value for manufacturing organizations. For instance, Avery Dennison, a Fortune 500 materials science leader with 36,000+ employees across 50+ countries, detected 358 BEC attacks within 90 days and identified 330 high-risk vendors requiring verification.

The platform stopped a $200,000 fraudulent invoice, protecting both company finances and critical vendor relationships. Additionally, their security team saved 40 hours weekly through automated remediation, allowing focus on strategic initiatives rather than manual threat hunting.

Ready to protect your production operations from advanced email threats? Get a demo or go through our customer stories to see how Abnormal can strengthen your manufacturing defenses.

Related Posts

Get the Latest Email Security Insights

Subscribe to our newsletter to receive updates on the latest attacks and new trends in the email threat landscape.